Providing engineering service for MES system

A manufacturing execution system (MES) is a software-based solution used in manufacturing to monitor and control production processes on the shop floor

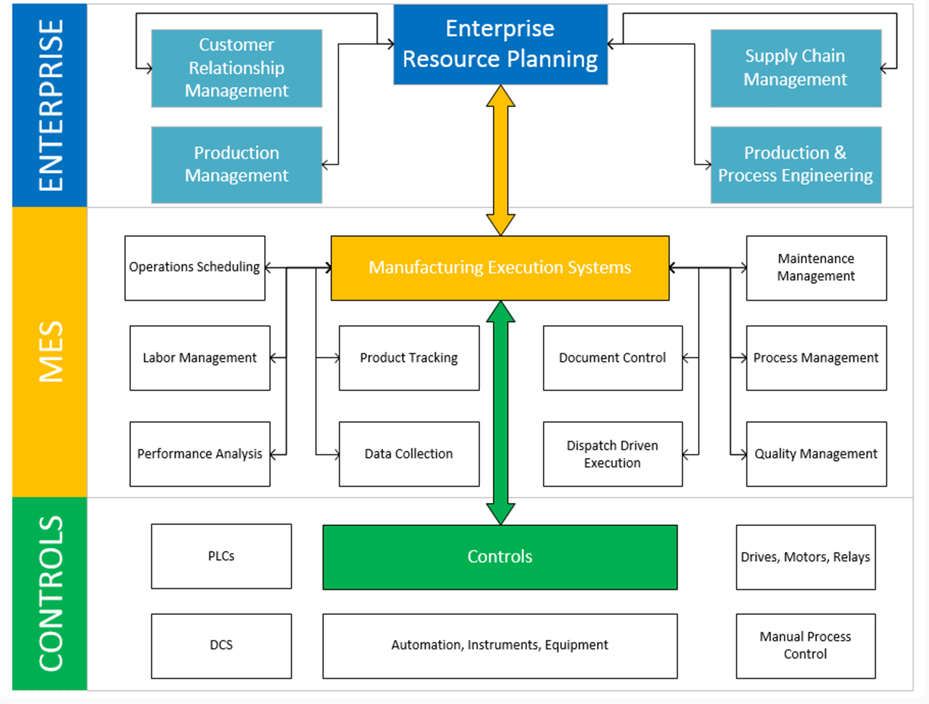

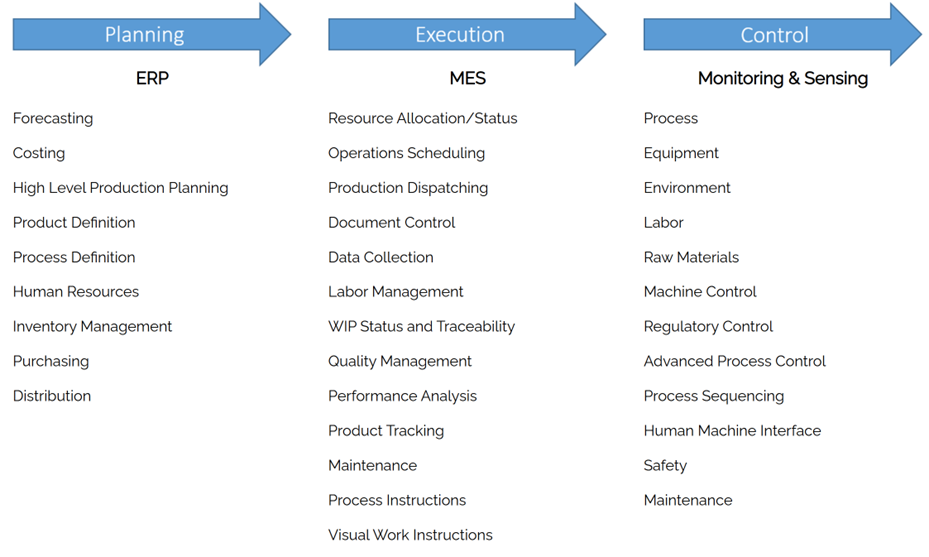

An MES is a software-based solution used in manufacturing to monitor and control production processes on the shop floor. In manufacturing operations management, an MES serves as a bridge between the planning and control systems of an enterprise, such as an enterprise resource planning (ERP) system, and the actual manufacturing operations.

The primary purpose of an MES is to track and document the transformation of raw materials into finished products in real time. It captures data from various sources, including machines, sensors and operators, to provide accurate and up-to-date information about the status of production activities.

An MES provides real-time visibility and control over production processes, enabling stakeholders to monitor operations, identify bottlenecks, minimize downtime and make informed decisions promptly. By facilitating optimized production planning and scheduling, MES systems ensure efficient resource allocation, workload balancing and on-time deliveries, leading to higher profitability.

They also play a critical role in quality assurance and compliance by enforcing quality control procedures, monitoring metrics and capturing real-time data. With their ability to manage inventory levels, track material movements and help ensure timely availability of materials, MES systems optimize inventory management and minimize production delays.

Moreover, MES systems enable data-driven decision-making by providing comprehensive and accurate production data, empowering organizations to continuously improve processes and optimize resource usage. MES systems can help decision-makers ascertain overall equipment effectiveness (OEE), a broad metric used to monitor manufacturing effectiveness.

By streamlining workflows, automating tasks and providing real-time feedback, MES systems enhance plant floor efficiency and productivity. Also, these management systems enable traceability and genealogy, crucial for industries with strict regulations, by tracking the movement of materials and processes throughout the smart manufacturing lifecycle.