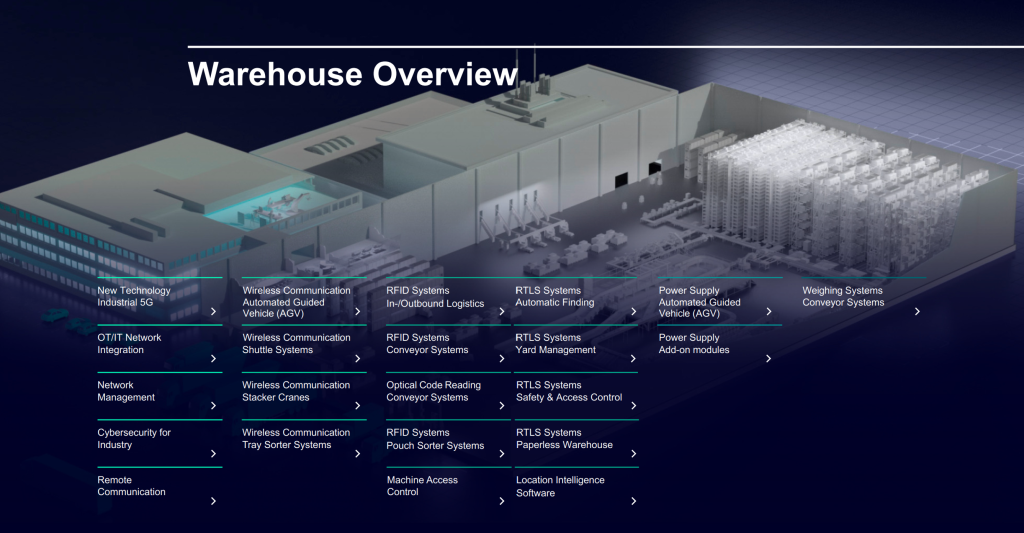

The Future of Warehousing is Digital

In the world of logistics, the warehouse is more than just a storage space—it’s the beating heart of the supply chain. Yet, many warehouses still rely on outdated, manual processes that lead to inefficiencies, errors, and significant operational costs. The solution to these challenges lies in digital distribution.

Digital distribution is the strategic application of technology to every aspect of warehouse operations, from inbound receiving to outbound shipping. It’s about creating a seamless, data-driven environment that connects people, equipment, and information to make the entire process faster, smarter, and more reliable.

Key Pillars of Digital Distribution in the Warehouse

-

Smart Warehouse Management Systems (WMS): The foundation of digital distribution is a powerful WMS. Unlike legacy systems, a smart WMS uses real-time data and advanced algorithms to optimize every movement within the warehouse. It can direct pickers along the most efficient path, intelligently allocate storage space based on demand, and automate inventory tracking with unparalleled accuracy.

-

Automation and Robotics: From automated guided vehicles (AGVs) that transport goods to robotic arms that sort and pack items, automation is revolutionizing warehouse operations. These technologies work tirelessly and accurately, reducing labor costs, speeding up order fulfillment, and minimizing the risk of human error and workplace injuries.

-

IoT and Connectivity: The Internet of Things (IoT) brings a new level of visibility to the warehouse. Sensors on pallets, shelves, and equipment provide real-time data on everything from temperature and humidity to location and status. This stream of information allows for proactive monitoring and maintenance, preventing issues before they disrupt operations.

-

Data Analytics and AI: The true power of digital distribution is its ability to turn data into a strategic asset. By applying artificial intelligence and machine learning to warehouse data, you can predict demand fluctuations, optimize workforce scheduling, and identify bottlenecks in your workflow. This level of insight allows for continuous improvement and a supply chain that can adapt to changing market conditions.

A Strategic Advantage

The transition to digital distribution is not just a technological upgrade; it’s a strategic move that provides a significant competitive advantage. It leads to faster order fulfillment, reduced errors, lower operating costs, and a more resilient and responsive supply chain.

By embracing digital distribution, you can transform your warehouse from a passive storage facility into a dynamic, intelligent hub that propels your business forward. The future of warehousing is here, and it’s digital.

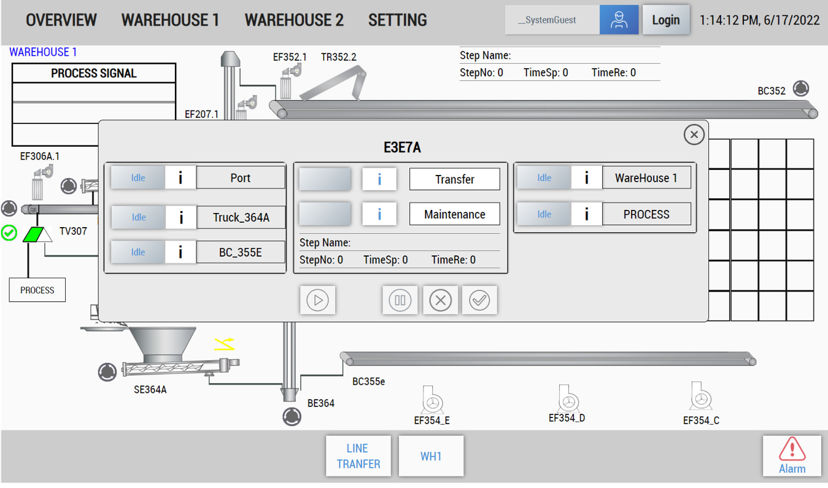

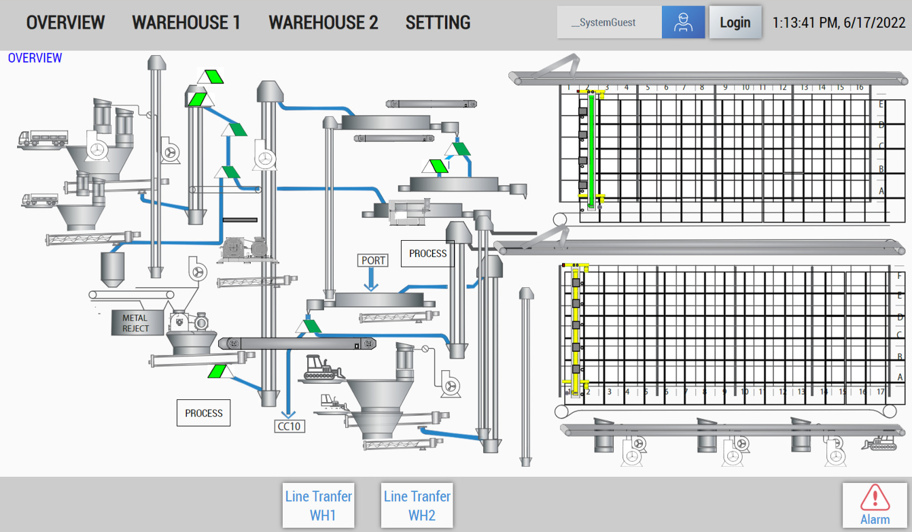

PROJECT REFERENCE

•1000m2 warehouse

•Motor control center 900A for conveyor, crusher, elevator

•Control System for gantry

•I/O count up to 500

For more information, do not hesitate to contact us.